| Control | |

|---|---|

| Sinumerik 828D system software (factory option) | SW 26x |

| CNC memory | 5 MB |

| Look Ahead | 100 |

| Set change time | 2 ms |

| Number of tools | 256 |

CNC lathe

OPTIturn L 50P

OPTIMUM PREMIUM Universal CNC Lathe with cycle control. Complete solution - Diverse possibilities

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3514340

Productdetails

- Precise processing

- SIEMENS spindle and feed motors

- Full enclosure with safety device

- Standard with max. spindle speed up to 3,500 min-1

- Hydraulic lathe chuck

- Ball screws

- Linear guides in all axes

- Automatic central lubrication

- Servo-hydraulic VDI 30 tool changer with 8 tool places

- Swivelling operating unit

- Electronic handwheels for X- and Z-axis

- Coolant system with 110 litre coolant tank

- RJ45 plug connection, USB connection and 230 V power connection

- EMC (electromagnetic compatibility)

- Six adjustable feet

- Operating tool

SINUMERIK 828D The powerhouse in the compact class of CNC controls

Increased productivity and precision in manufacturing

Robust hardware architecture and intelligent control algorithms as well as top-class drive and motor technology ensure maximum dynamics and accuracy in machining. Advanced software-controlled compensation functions ensure additional quality in surface machining and high machine tool availability. With SINUMERIK Operate, all machining technologies, from standard to complex, can be operated intuitively and with a uniform "look & feel".

SINUTRAIN

- NC programming on the PC as on the CNC - same operation and programming

- Work preparation while the machine is still clamping: Test, run-in and simulate NC programs on the PC - less time stress at the machine

Multitouch operation with PPU 290

The 15.6" panel is robust even in harsh environments. The SINUMERIK Operate user interface is optimized for touch-sensitive operation.

User-friendly

- Capacitive 15.6" color display in 16:9 format

- Configurable sidescreen

- Intuitive multi-touch operation

- Full QWERTY keyboard

- Softkey selection via touch function

- Easy data transfer via IP65 protected front interfaces (USB 2.0, RJ45 Ethernet)

- Proximity sensor for smart display control

Robust and maintenance-free

- Magnesium die-cast panel front with scratch-resistant glass front

- Can be operated with work gloves

- NV-RAM memory technology without buffer battery

- Fan- and hard disk-less design

- CNC education and training with exactly the same programming and operating interface as in the workshop - without waiting for it to "finally get to it", without the risk of breaking something - and with the possibility of doing preparatory and follow-up work at home or on the road.

DXF-READER

- Faster from the drawing to the component. Easy transfer of CAD data to programming with DXF-READER (optional article no. 3584014).

Siemens Safety Integrated

Functional safety also protects against high costs!

Machine and system safety is not only important because strict regulations must be observed. If everything runs safely, you benefit from time savings in engineering, higher plant availability and more investment security.

Total package

- Safety Integrated

- Residual material recognition and machining

- ShopTurn work step programming

- Manage network drive

- 3-D simulation

- Draw in

- System software SW 26x

Equipment

Main spindle

- Massive design

Ball screw

- Ground

- High rapid traverse speeds

- Less wear

- High positioning and repeat accuracy

Machine bed

- Heavily ribbed

- High rigidity and durability

Machine feet

- Six pieces

- Optimal alignment of the machine

| Cooling lubricant system | |

|---|---|

| Coolant pump output | 450 W |

| Tank capacity | 110 l |

| Cleaning pump output | 1 kW |

| Dimensions and weights | |

|---|---|

| Length approx. | 3190 mm |

| Width/depth approx. | 1965 mm |

| Height approx. | 2052 mm |

| Weight approx. | 4500 kg |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed speed | |

|---|---|

| X axis | 15 m/min |

| Z axis | 20 m/min |

| Hydraulic system | |

|---|---|

| Motor output | 2,2 kW |

| Tank capacity | 50 l |

| Machine data | |

|---|---|

| Chuck passage diameter | 52 mm |

| Motor torque | |

|---|---|

| X axis | 6 Nm |

| Z axis | 11 Nm |

| Motor(s) | |

|---|---|

| Torque at the spindle | 95 Nm |

| Precision | |

|---|---|

| Repetition accuracy | ±0.005 mm |

| Positioning accuracy | ±0.005 mm |

| Spindle | |

|---|---|

| Spindle chuck | ISO 702-1 No. 6 Form A2 |

| Spindle bore/rod passage diameter | 66 mm |

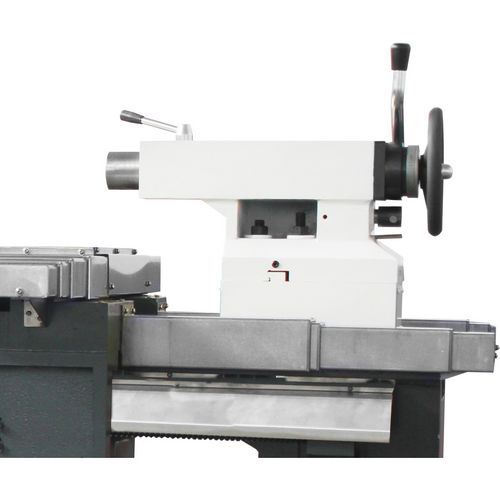

| Tailstock | |

|---|---|

| Chuck | MK 5 |

| Quill stroke | 150 mm |

| Quill diameter | 75 mm |

| Travel | |

|---|---|

| Travel X axis | 300 mm |

| Travel Z axis | 800 mm |

| Turret | |

|---|---|

| Type | Hydraulic Servo. VDI 30 |

| Number of tool slots | 8 St |

| Max. chuck height, width square | 20 mm |

| Max. chuck diameter drilling rod | 32 mm |

| Vertical spindle | |

|---|---|

| Drive motor output continuous operation S1 | 9 kW |

| Drive motor output S6-30 % operation | 15.8 kW |

| Drive motor torque | 57 Nm |

| Drive motor torque S6-30 % operation | 95 Nm |

| Work areas | |

|---|---|

| Lathe chuck diameter | 210 mm |

| Turning length | 618 mm |

| Max. height | 245 mm |

| Swing diameter above machine bed | 490 mm |

| Swing diameter above planing slide | 280 mm |

| Bed width | 400 mm |

| VPE | 1 |

Packaging unit: 1

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.