| Cooling lubricant system | |

|---|---|

| Coolant pump output | 95 W |

| Tank capacity | 25 l |

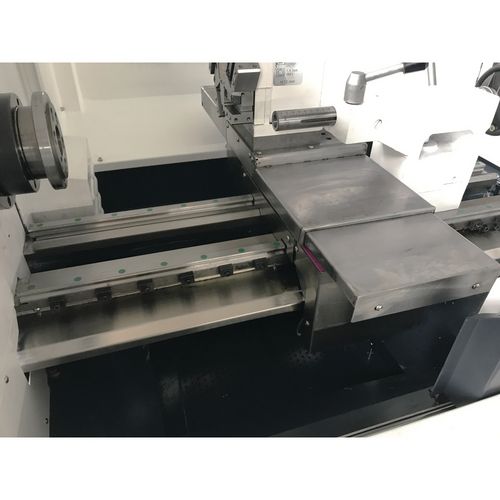

CNC-controlled flatbed lathe

OPTIturn L 28HS SINUMERIK 808D ADVANCED

CNC-controlled flatbed lathe with linear guide. Control via Siemens 808D Advanced.

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3504220

Productdetails

- Braced machine bed made of gray cast iron

- Elaborate spindle bearing

- Emergency stop impact switch

- Central lubrication

- Reference switch

- Maintenance-friendly protective housing

- Rear access door for maintenance

- Safety switch on the front sliding door

- Revolving revolver is behind the center of rotation (left-hand turning tool)

- Linear guide

- Software package "SINUMERIK 808D on PC" included. (Practical training software, with it Workpieces can be programmed and simulated offline on the PC. Download for free at www.cnc4you.com)

| Dimensions and weights | |

|---|---|

| Length approx. | 1655 mm |

| Width/depth approx. | 1590 mm |

| Height approx. | 1955 mm |

| Weight approx. | 832 kg |

| Electrical connections | |

|---|---|

| Total rated value | 3.75 kVA |

| Electrical Data | |

|---|---|

| Drive motor output | 2,2 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed speed | |

|---|---|

| X axis | 10000 mm/min |

| Z axis | 12000 mm/min |

| Hydraulic system | |

|---|---|

| Tank capacity | 25 l |

| Motor torque | |

|---|---|

| X axis | 1.3 nm |

| Z axis | 2,4 Nm |

| Motor(s) | |

|---|---|

| Drive motor torque | 14 nm |

| Torque at the spindle | 28 nm |

| Precision | |

|---|---|

| Repetition accuracy | ± 0.01 mm |

| Positioning accuracy | ± 0.01 mm |

| Speed range | |

|---|---|

| Speed range | 40 – 4000 min¯¹ |

| Spindle | |

|---|---|

| Spindle chuck | (DIN 6350) A2-3 |

| Spindle bore/rod passage diameter | 30 mm |

| Spindle taper | 5C |

| Tailstock | |

|---|---|

| Chuck | MK2 |

| Quill stroke | 120 mm |

| Quill diameter | 30 mm |

| Travel | |

|---|---|

| Travel X axis | 145 mm |

| Travel Z axis | 465 mm |

| Turret | |

|---|---|

| Type | electrical |

| Number of tool slots | 6 St |

| Max. chuck height, width square | 16 mm |

| Max. chuck diameter drilling rod | 16 mm |

| Work areas | |

|---|---|

| Max. height | 169 mm |

| Max. width | 430 mm |

| Swing diameter above machine bed | 300 mm |

| Swing diameter above planing slide | 200 mm |

| Bed width | 180 mm |

| VPE | 1 |

Packaging unit: 1

- Coolant system

- machine lamp

- operating tool

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.