- State-of-the-art SINUMERIK ONE CNC control from Siemens with a wide range of functions that significantly increase both productivity and flexibility (detailed information in the OPTIMUM CNC main catalog)

- Heavy-duty design

- High productivity

- Telescopic guideway cover

- Precision-ground, preloaded high-performance ball screws for high rapid traverse speeds

- Spindle mounted in P5 precision bearings and permanently lubricated

- High-torque servo drives in all five axes

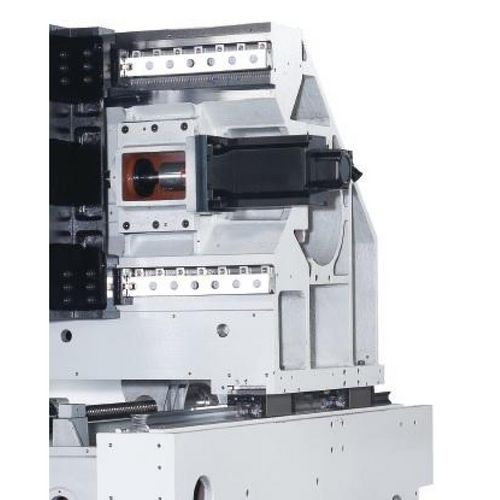

- Precision linear guide

- Heidenhain glass scales for higher accuracy

- High rapid traverse speed of up to 24 m/min. in X, Y and Z axes

- A/C axis with torque motor for maximum speed and lifetime accuracy

- The portable, electronic handwheel with enabling switch and emergency stop switch makes it much easier to run in programs

- Tool changer double-arm gripper with 60 tool positions included as standard

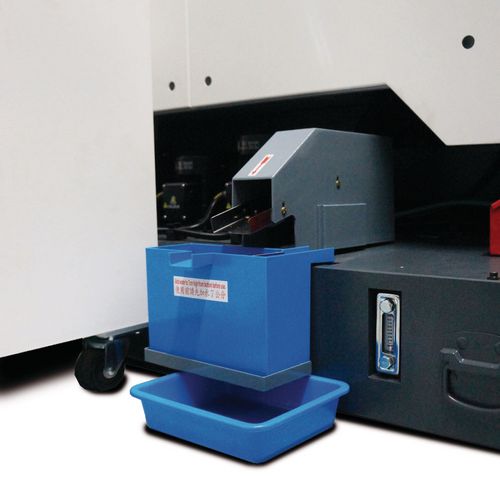

- Coolant system with 480 liter coolant tank with chip flushing system and cleaning gun

- Automatic central lubrication

- RJ45 plug connection, USB and 230 V power connection

- Additional USB interface on the control panel

- Water circuit cooling unit for the main spindle and main spindle motor as well as for the A and C axes

- Chip conveyor in belt design ensures efficient chip removal

- Chip trolley

- Collision Avoidance - software for collision avoidance

- Internal tool cooling 70 bar with internal tank (an extraction system is recommended)

- Heat exchanger

- EMC (electromagnetic compatibility)

- Two-year Siemens repair service contract included. Extension of the Siemens additional package repair service contract (RSV) possible

- State-of-the-art SINUMERIK ONE CNC control system from Siemens

- Heavy-duty design

- High productivity

- Precision-ground, preloaded high-performance ball screws for high rapid traverse speeds

- Precision linear guide

- Heidenhain glass scales for higher accuracy

- Tool changer double-arm gripper with 60 tool positions included as standard

- Water circuit cooling unit for the main spindle and main spindle motor as well as for the A and C axes

- Chip conveyor in belt design ensures efficient chip removal

- Collision Avoidance - software for collision avoidance

- Internal tool cooling 70 bar with internal tank (an extraction system is recommended)

| Cooling lubricant system |

|---|

| Tank capacity external CTS unit | 165 l |

| Dimensions and weights |

|---|

| Length approx. | 2880 mm |

| Width/depth approx. | 4290 mm |

| Height approx. | 3480 mm |

| Weight approx. | 14500 kg |

| Electrical connections |

|---|

| Total rated value | 70 kVA |

| Electrical Data |

|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed |

|---|

| X axis | 24000 mm/min |

| Y axis | 24000 mm/min |

| Z axis | 24000 mm/min |

| Feed force |

|---|

| Feed force X-axis | 10 kN |

| Feed force Y-axis | 10 kN |

| Feed force Z-axis | 13.5 kN |

| Feed motor torque |

|---|

| X axis continuous operation S1 | 22 Nm |

| Y axis continuous operation S1 | 22 Nm |

| Z axis continuous operation S1 | 27 Nm |

| Milling table horizontal |

|---|

| Table length | 600 m |

| Table width | 500 mm |

| T-groove size | 14 mm |

| Max. load bearing capacity | 400 kg |

| Pneumatic connection |

|---|

| Operating pressure | 6 bar |

| Precision |

|---|

| Repetition accuracy | ± 0.004 mm |

| Positioning accuracy | ± 0.008 mm |

| Product information EU 2023/2854 |

|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Pump |

|---|

| Pump motor chip flushing | 0.85 kW |

| Pump motor chip flushing conveying rate | 150 l/min |

| Pump motor front/left chip flushing | 1.08 kW |

| Pump motor front/left chip flushing delivery rate | 150 l/min |

| Pump motor cleaning gun | 0.53 kW |

| Pump motor cleaning gun delivery rate | 58 l/min |

| Rotary axis |

|---|

| Swivel axis | ± 120 ° |

| Rotation axis | 360 ° |

| Max. speed A axis | 100 min¯¹ |

| Max. speed C axis | 120 min¯¹ |

| Tilting and rotating table |

|---|

| Hydr. clamping torque swivel axis C (50bar hydraulic pressure) | 850 Nm |

| Hydr. clamping torque swivel axis A (50bar hydraulic pressure) | 850 Nm |

| Travel |

|---|

| X axis automatic | 800 mm |

| Y axis automatic | 740 mm |

| Z axis automatic | 600 mm |

| Turret |

|---|

| Design | Double arm gripper |

| Number of tool slots | 60 |

| Max. tool diameter adjacent slots free | 90 mm |

| Max. tool diameter | 78 mm |

| Max. tool length | 300 mm |

| Max. tool weight | 8 kg |

| Tool change time chip to chip (C to C) | 3 s |

| Vertical spindle |

|---|

| Spindle chuck | HSK 63 |

| Speed | 15000 min¯¹ |

| Drive motor output continuous operation S1 | 25 kW |

| Drive motor output S6-30 % operation | 40 kW |

| Torque drive motor continuous operation S1 | 105 Nm |

| Torque drive motor S6-30 % operation | 261 Nm |

Unit: pc(s).

Packaging unit: 1

Optimum Maschinen Germany GmbH

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de