| Dimensions and weights | |

|---|---|

| Length approx. | 620 mm |

| Width/depth approx. | 330 mm |

| Height approx. | 580 mm |

| Weight approx. | 53 kg |

TIG Inverter

INVERTIG i 350 AC/DC HIGH

State-of-the-art inverter technology and intuitive SIRIUS user interface

10.690,00

EUR excl. Tax / pc(s).

12.828,00

EUR incl. 20% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 1408135

Productdetails

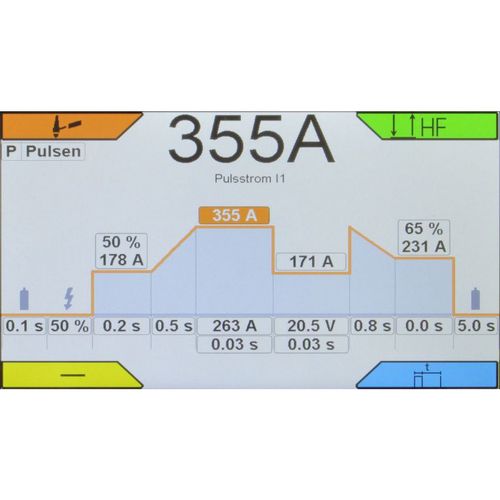

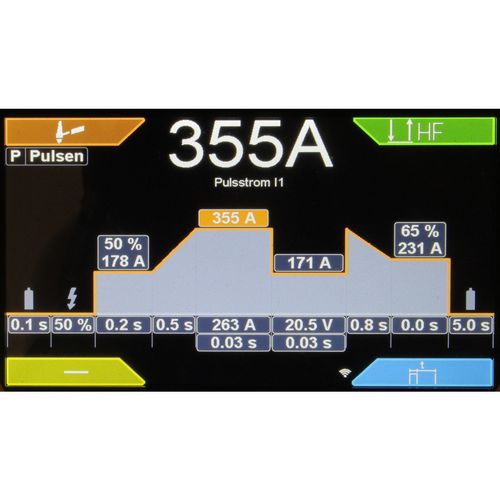

Intuitive fourth-generation SIRIUS user interface

- Graphically dynamic and transparent visualization

- Easy operation of complex digitally controlled processes

Highly efficient welding processes with a perfect arc

- DC welding: directionally stable from 5 A; For sheet thicknesses from 0.2 mm

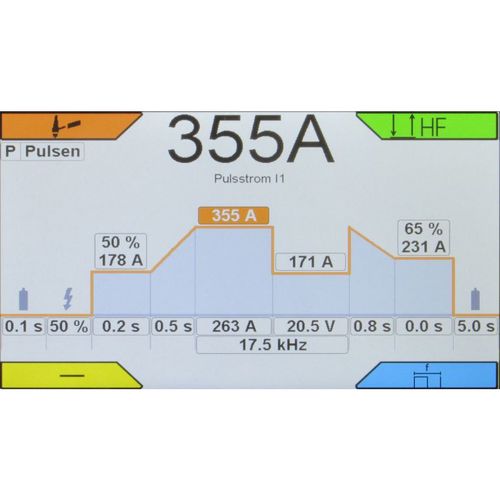

- DC hyper.pulse welding: the welding current is constricted at up to 17,500 Hz. This results in a significantly higher energy density in the arc and on the workpiece

- DC Hyper.Spot tack welding: Significant reduction of distortion and tarnish. All stapling applications without air gap. Identical tackers enable a uniform weld seam

- Interval Welding: Targeted heat application to the spot. Optimal for tool repair or buildup welding.

- AC Welding: Optimal for aluminum, cladding, brackets and structures, frames and tanks, repair welding.

- AC waveforms: Soft sine, hard sine, triangle, and rectangle.

- AC frequency automatic: Protects the electrode in the upper and increases stability in the low power range

- AC-Balance: Optimized AC balance protects the electrode and increases the welding speed

- AC-Hyper.Pulse: Aluminum tacking without filler metal for thin-walled components, HYPER.PULS also operates at AC with up to 17,500 Hz

- AC-HYPER.SPOT: Aluminum tacking without filler metal. All tacking applications without air gap

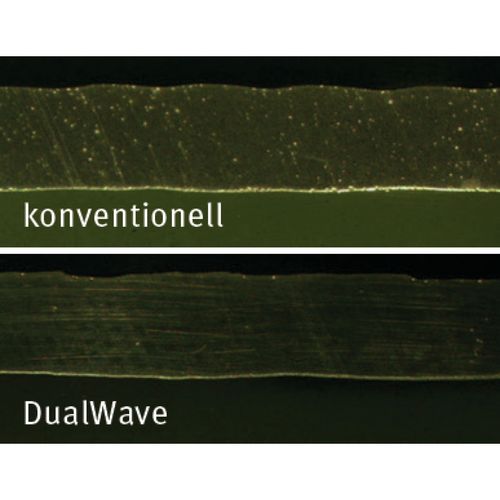

- AC-DualWave: Reduction of pore formation for aluminum with different material thicknesses, aluminum tank construction.

| Duty cycle | |

|---|---|

| at Imax. 40°C TIG DC | 80 % |

| Current at 100% DC 40°C TIG DC | 340 A |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Power consumption | |

|---|---|

| TIG DC | 10.2 kVA |

| Setting range | |

|---|---|

| TIG DC | 5 – 355 A |

| VPE | 1 |

Packaging unit: 1

| Hyperpulse | 17500 Hz |

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.