| Dimensions and weights | |

|---|---|

| Length approx. | 2200 mm |

| Width/depth approx. | 1160 mm |

| Weight approx. | 450 kg |

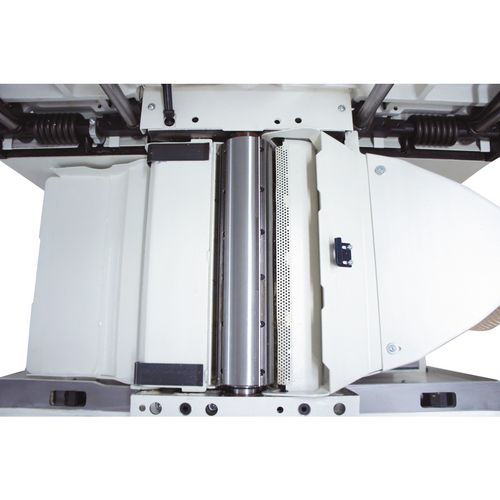

Surface and thickness planer

minimax fs 41s TERSA Digital

Maximum equipment for the professional. Digital version with motorized thickness table adjustment.

15.180,00 EUR incl. 20% Tax / pc(s).

Promotional price *

10.299,00 EUR excl. Tax / pc(s).12.358,80 EUR incl. 20% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

* Promotional price valid until 28.02.2025 in Germany.

Art.-No. 5503441

Productdetails

- Slanted toothed steel feed roller for constant and even material intake, resulting in chip removal from as little as 0.2 mm (with min. workpiece thickness of 3 mm). workpiece thickness of 3 mm) - ideal for economical planing of precious wood

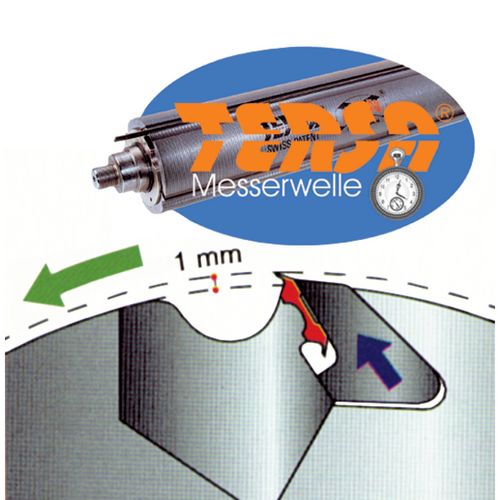

- Models with TERSA cutterblock for changing planing knives in seconds and particularly quiet running

- Material feed with two speeds

- Extremely long dressing tables enable easy and precise dressing of workpieces

- Working tables made of grey cast iron, annealed and stress-free, thus insensitive and permanently flat

- To the rear, rear-opening, simultaneous dressing tables for short set-up times

- Plane thickness table adjustment via handwheel with numerical display for plane height

- Digital models with motorised thickness table adjustment

- High machine weight for highest precision and smooth running

- Powerful industrial motor

- Robust steel/cast iron construction

- Quality - Made in Italy

| Electrical Data | |

|---|---|

| Drive motor output | 5 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Extraction port | |

|---|---|

| Extraction port diameter thickness | 1 x 120 mm |

| Feed | |

|---|---|

| Speed | 6 / 12 m/min |

| Jointing | |

|---|---|

| Max. cutting depth | 5 mm |

| Planing stop pivoting range | 90 – 45 ° |

| Planing knife shaft | |

|---|---|

| Type | TERSA |

| Number of planing blades | 4 St |

| Speed | 5000 min¯¹ |

| Max. planing width | 410 mm |

| Thickness | |

|---|---|

| Working height min. | 3 mm |

| Working height max. | 240 mm |

| Max. cutting depth | 5 mm |

| VPE | 1 |

Packaging unit: 1

- Dressing join fence with round bar guide & auxiliary fence

- Two feed speeds

- Tersa planer shaft

- Electric thicknessing table height adjustment

- Digital display

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.