- Hardened and ground Z-axis guideway

- Guaranteed concentricity of the spindle nose ≤ 0.015 mm

- Spindle holder Camlock DIN ISO 702-2 No. 8

- Lead screw cover

- Precisely machined slide

- All guides can be adjusted using gibs

- Right/left rotation on bed slide switchable via switching spindle

- Two-channel safety electronics

- Central lubrication in the bed slide

- Upper slide adjustment range ± 90

- Main spindle runs in oil bath

- Shafts and wheels running in oil bath

- Gear wheels smooth-running, hardened, ground and mounted with 2 adjustable precision tapered roller bearings

- Switch with life cycle calculation, tested in accordance with EN ISO 13849

- Handwheels with adjustable fine scaling 0.04 / 0.02 mm

- Safety handwheels with disengagement function in accordance with EN23125 in the X and Z axes

- Gear wheels and shafts hardened and ground, running in an oil bath in precision bearings

- Clearly arranged selector lever for switching the feed speeds

- Closed design of the high-speed feed gearbox

- Emergency stop impact switch, motor protection switch, lockable main switch

- Emergency stop device with foot actuation

- Tailstock for taper turning ± 10 mm adjustable

- Tailstock quill and handwheel with adjustable fine scaling 0.025 mm. Quick, easy and tool-free adjustment by means of clamping lever

- Energy chain for gentle cable and hose guidance

- Heavily ribbed prism bed, induction-hardened and precision-ground from gray cast iron

- Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning in accordance with DIN

- Adjustable scale of the thread gauge

| Cooling lubricant system |

|---|

| Coolant pump output | 125 W |

| Dimensions and weights |

|---|

| Length approx. | 2950 mm |

| Width/depth approx. | 1150 mm |

| Height approx. | 1650 mm |

| Weight approx. | 2300 kg |

| Electrical Data |

|---|

| Drive motor output | 7,5 kW |

| Total rated value | 8.5 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed |

|---|

| Longitudinal feed range | 0,059 – 1,646 mm/rev |

| Number of longitudinal feeds | 35 |

| Flat feed range | 0,020 – 0,573 mm/rev |

| Number of flat feeds | 35 |

| Pitches |

|---|

| Metric pitch | 0,2 – 14 mm/rev |

| Number of metric pitches | 47 |

| Imperial pitch | 112 – 2 Gg/1" |

| Number of imperial pitches | 60 |

| Diametrical pitch | 4 – 112 DPI |

| Number of diametrical pitches | 50 |

| Modular thread pitch | 0,1 – 7 mm/rev |

| Number of modular thread pitches | 34 |

| Speed range |

|---|

| Number of gears | 12 |

| Speed range | 25 – 1600 min¯¹ |

| Spindle |

|---|

| Spindle chuck | Camlock DIN ISO 702-2 No. 8 |

| Spindle bore/rod passage diameter | 80 mm |

| Tool holder max. chuck height | 25 mm |

| Spindle cone | MT 7 |

| Tailstock |

|---|

| Chuck | MK 5 |

| Quill stroke | 180 mm |

| Quill diameter | 75 mm |

| Travel |

|---|

| Travel upper slide | 130 mm |

| Travel cross slide | 316 mm |

| Travel carriage saddle | 1210 mm |

| Work areas |

|---|

| Max. height | 280 mm |

| Max. width | 1420 mm |

| Swing diameter above machine bed | 560 mm |

| Swing diameter in bed bridge | 790 mm |

| Swing diameter above planing slide | 355 mm |

| Turning length in bed bridge | 170 mm |

| Bed width | 350 mm |

Unit: pc(s).

Packaging unit: 1

- Fixed bezel passage max. Ø 165 mm

- Running bezel passage max. Ø 95 mm

- LED machine light

- TH 5615D-TH 5630D: Reduction sleeve MK 7 / MK 5

- TH 5620V: Reduction sleeve Ø 113 mm / MK 5

- Fixed centering point MK 5

- Fixed and revolving centering point MK 5

- Quick change steel holder 7-C

- Steel holder 32 x 150 type D for square chisels

- Threading gauge

- Initial machine filling with quality oil

- Change gear set

- operating tool

Do not forget the lathe chuck!

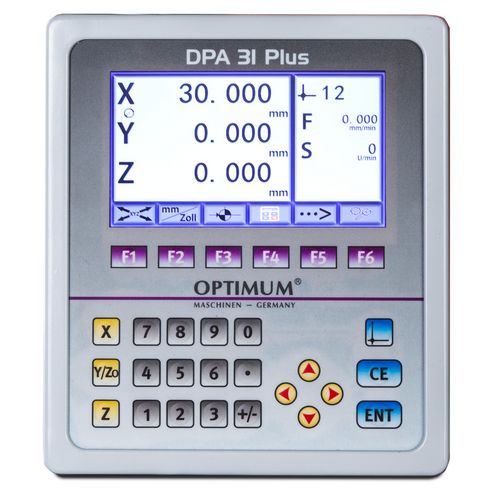

| Digital position indicator | DPA 31 Plus |